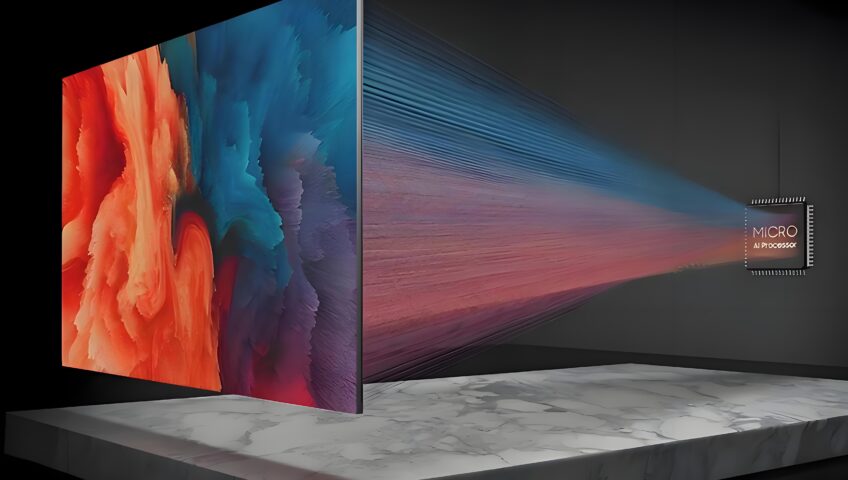

Indoor LED Displays revolutionized the way businesses reach out to customers. Captivating high quality video, images, and text content can be displayed on the screens. Shenzhen Geshino Technology Company Ltd. is one of the companies that provides these displays.

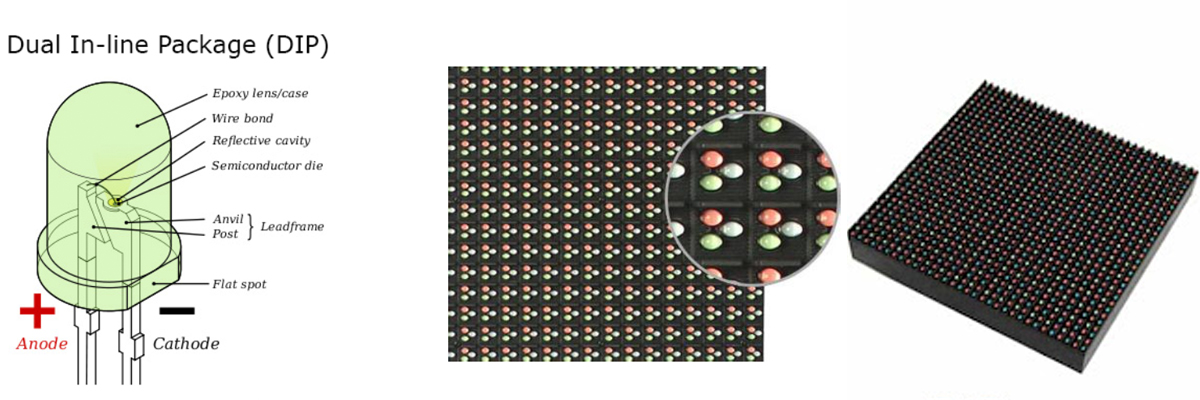

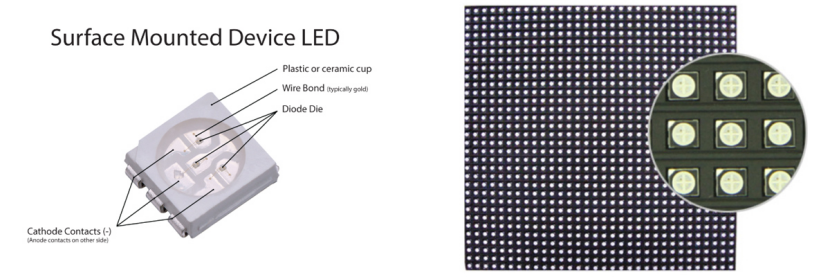

An indoor LED display is made of thousands of small lights that can be clustered together and used to make images. With advancements in technology, these displays can be used in stores, offices, and event spaces.

Most modern indoor LED displays are built to provide high performance on a daily basis. “A high quality indoor LED display should be able to maintain stable performance whether it is used for a long time or in high ambient envinronmental conditions.” In other words, it should maintain high display quality after long hours of use.

What Makes Indoor LED Displays Special

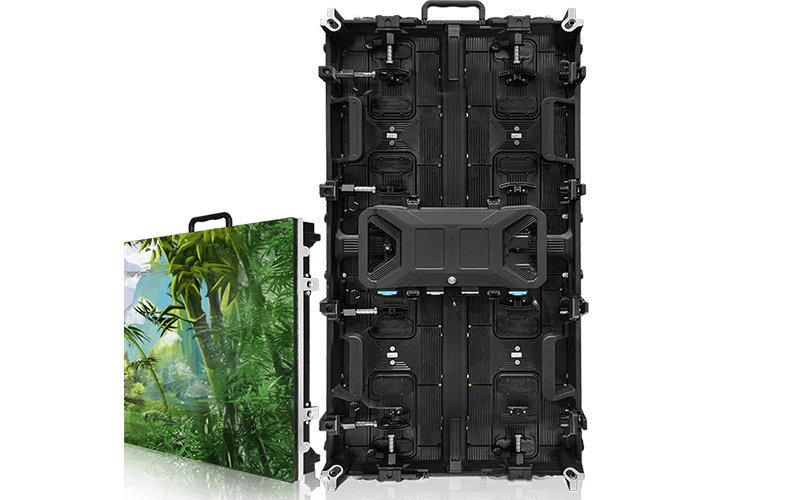

Geshino indoor fixed displays are built using high quality parts. Quality of a display directly affects its performance and durability. Geshino has built a reputation for high quality parts by focusing on durability in daily use. Respect.

As with any display technology, indoor LED displays require robust construction because they operate for extended hours. Since they generate heat during operation, adequate cooling systems are essential. “The cabinet also contains the necessary ventilation and cooling systems to maintain optimal operating temperatures for the LEDs.” This ensures the display meets the cooling requirements.

Factoring the cooling requirements for the cabinet means the display will utilize the best LED chips and control systems. When quality materials are incorporated.

Long-Term Reliability and Performance

The best indoor LED displays provide excellent functionality and service for several years. Geshino LED displays are designed with the daily use requirements for businesses in mind. It does not matter if the display is used in a store for 12 hours a day, or used in an office for presentation purposes, the displays will not fail.

Reliability encompasses all aspects, from power-on to content display, to color brightness, and even to the absence of dimming or linear blotching. Quality displays are designed for over 100,000 hours of use, translating to over 11 years of daily operation.

Applications: Where Indoor LED Displays Work Best

Retail Environments

Using indoor LED displays is a common practice in stores since they capture attention. They can display promotional product videos, informative sales messages, and brand marketing. “LED screens can also be used as part of stage designs for live events, concerts, and performances, adding visual impact and enhancing the overall experience for the audience.”

In retail spaces, displays help customers find what they need. They can show directions to different departments or highlight special offers. The bright, clear pictures make it easy for shoppers to see information from across the store.

Geshino LED displays work great in retail because they are dependable. Stores can’t afford for displays to fail during peak shopping times. Displays work continuously, ensuring stores transmit messages to customers.

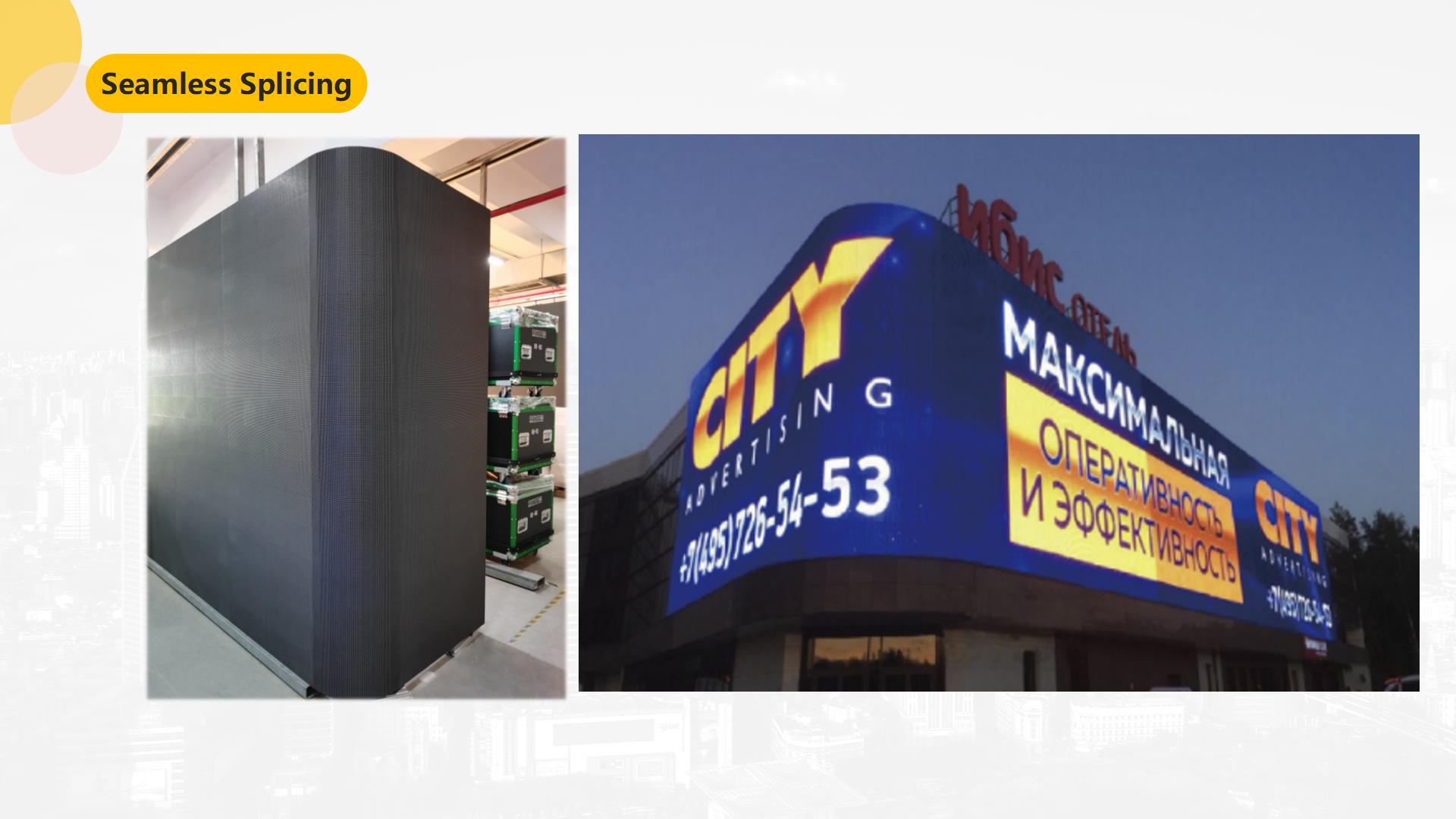

Events and Conferences

Making events more exciting and informative is the other major advantage of indoor LED displays. “A stage video wall is a large, seamless LED display used in concerts, conferences, theaters, and live events to create immersive visual experiences.” People at events can see presentations clearly, even from the back of the room.

These types of displays are used in conference centers to present information about speakers, schedules, and sponsors. Since content is easily adaptable, organizers can refresh displays multiple times a day.

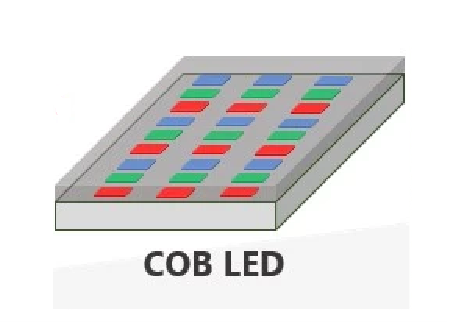

Business and Office Settings

Indoor LED displays in offices are used during meetings, training sessions, and lines of communication to employees. “Its characteristics include high stability, fixed installation design, and long-term display.” This makes them ideal for conference rooms, which require long-term stable displays to show content in varying sized texts and images to distant viewers.

Corporate lobbies frequently feature large welcome displays that streamline guest visitation and relay important corporate information. This aids in creating a positive professional area that enhances sponsorship of corporate branding.

Key Features of Quality Indoor LED Displays

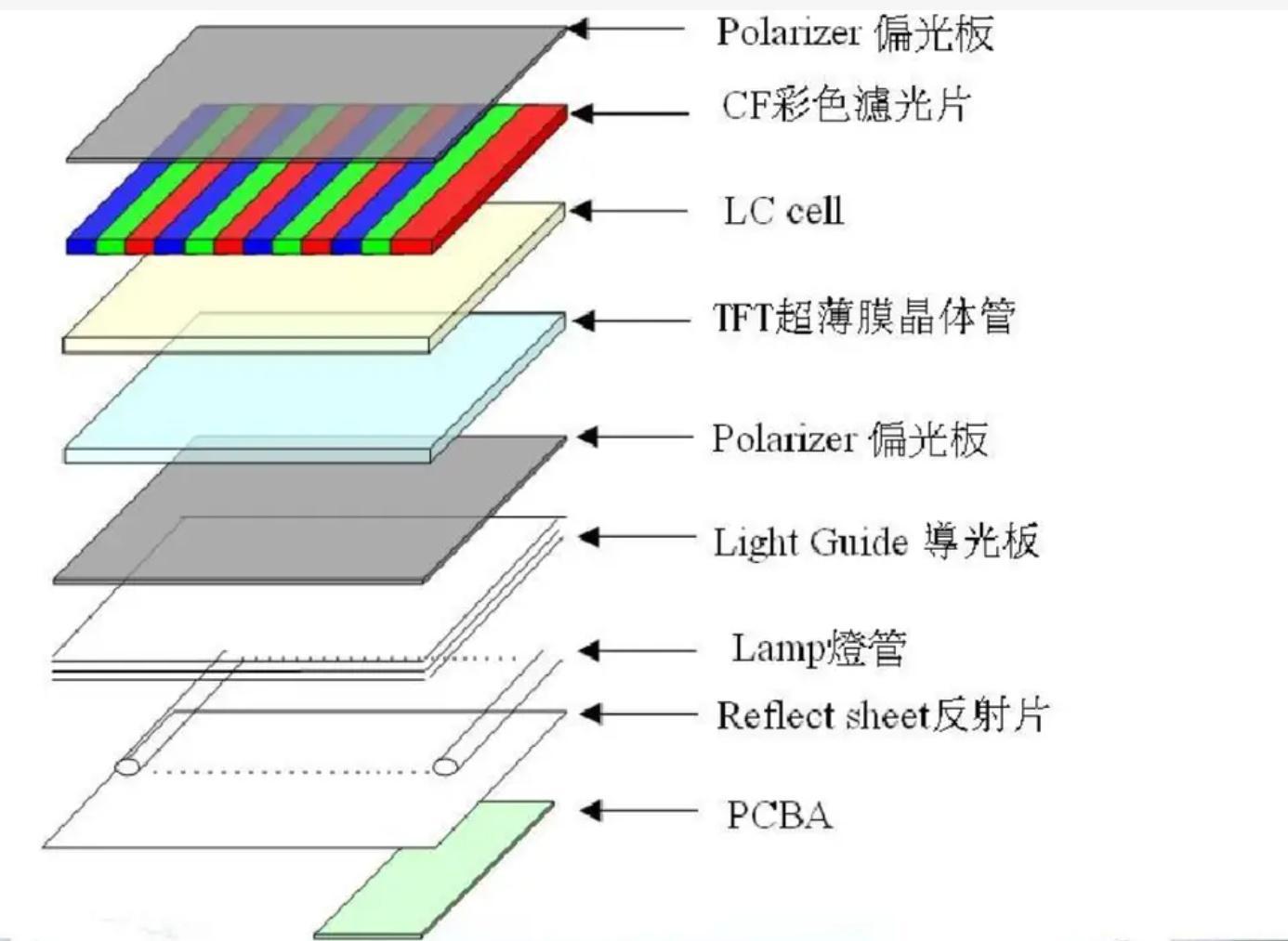

Superior Image Quality

At the highest level, indoor LED displays produce images and clips at the highest quality. Colors are bright, realistic and a varying range of tones. Details are distinct and sharp at all lengths, even close up. “Key benefits of LED displays include vivid color reproduction, a wide dynamic range, high brightness levels, long operational lifespan, and reliable performance.”

Multiple factors affect the quality of the image, one of which is pixel pitch. This is the distance between the LED components and the optical axis. The smaller the pitch, the more defined the image.

Frequently Asked Questions

Q. How long do indoor LED displays last?

A. Quality indoor LED displays like those from Geshino are rated to last 100,000 hours and over, which is 11 years of daily use non-stop.

Q. What makes Geshino displays different from the rest?

A. Geshino indoor fixed LED displays are constructed with quality materials for designed long-term reliability which is why they are suitable for daily business use.

Q. Can indoor LED displays work for all kinds of businesses?

A. Absolutely. Geshino LED displays are reliable and versatile, which is why they excel in retail stores, offices, conference centers, and event venues.

Q. Do indoor LED displays consume a lot of electricity?

A. No. Advanced indoor LED displays are energy-efficient, and with the latest technology, they use less power than older displays while delivering brighter and clearer images.

Q. How bright should an indoor LED display be?

A. Indoor LED displays typically perform best within a brightness range of 800 to 1,500 nits. This is bright enough to be seen clearly without discomfort.

Q. What pixel pitch is best for indoor use?

A. The best pixel pitch for indoors varies depending on how far away a person is. 1.5-2.5mm works for close viewing. 3-6mm is typically sufficient for farther viewing.

Conclusion

Businesses can enhance their interaction with customers and employees using indoor LED displays. Attention-grabbing content can be conveyed using images that are sharp and bright. Geshino Technology Company Ltd. is known for reliable displays and quality service.

Reliable and long-lasting Geshino indoor fixed LED displays are constructed from high-grade materials. These displays are flexible and can be used for different purposes, be it for retail, events, conferences, or office use. Their long-lasting reliability saves you from periodic maintenance downtime.

The longevity, picture quality, and energy efficiency of indoor LED displays will enhance their functionality. With innovative, unique encapsulation technologies, Hikvision indoor LED displays provide excellent visual elements and clarity. Such advancements reach customers who prioritize the functionality and quality of the latest displays.

Identifying the purpose of the indoor LED display will guide you in making the right choice. Geshino LED displays are versatile, making them an excellent option for any business or purpose. TTaking into account the distance of the audience and the type of content, you can determine the intended use.